How to Develop High-Quality UV Sterilisation Equipment: Technical Insights for Brand and ODM Collaboration

As public awareness of hygiene and health reaches unprecedented levels, demand for efficient and reliable disinfection solutions continues to grow across various sectors—from personal care and household cleaning to medical, catering, logistics, and public facilities. As a specialist ODM disinfection devices manufacturer, we have observed an increasing number of brand partners actively exploring the development of differentiated, high-quality special disinfection devices to expand their product portfolios and seize early market opportunities.

Ultraviolet (UV) sterilisation, thanks to its broad-spectrum efficacy, rapid action, environmental friendliness, and ease of integration, is undoubtedly a preferred technology in many advanced cleaning solutions. However, transforming this technology into a safe, effective, and durable product is far from simple. Even minor deviations in design may result in significantly reduced germicidal efficacy, shortened device lifespan, or even safety risks.

Suppose you are planning to add a high-quality UV disinfection device to your product line. In that case, this blog will shed light on the core technical features of UV sterilisation and provide a detailed analysis of the essential principles to follow during design. Mastering these principles will help you avoid common pitfalls in development and procurement, enabling you to create more competitive products.

Key Characteristics of UV Sterilisation Technology

Broad-spectrum efficacy: UV light is highly effective at destroying microorganisms. It damages the DNA or RNA of microbes (such as bacteria, viruses, and mould spores), preventing them from replicating and thereby rendering them inactive. It is effective against most common pathogens, including E. coli, Staphylococcus aureus, influenza viruses, and coronaviruses.

Rapid action: Given sufficient dosage, UV light can inactivate microorganisms within seconds to minutes.

Environmentally friendly: UV sterilisation is a purely physical process and does not require chemical disinfectants. Thus, there is no risk of harmful chemical residues or antimicrobial resistance, making it more environmentally sustainable (note: ozone generated under certain conditions requires special handling, see below).

Easy to integrate: UV light sources (e.g. mercury lamps, UV LEDs) are relatively compact, making them easy to incorporate into various product forms with automated control systems.

Core Design Principles for UV Sterilisation Devices

1、Principle of Effective Sterilisation

Achieving effective and efficient sterilisation is the primary design goal of any disinfection device. To design a functional UV sterilisation product, the following must be observed:

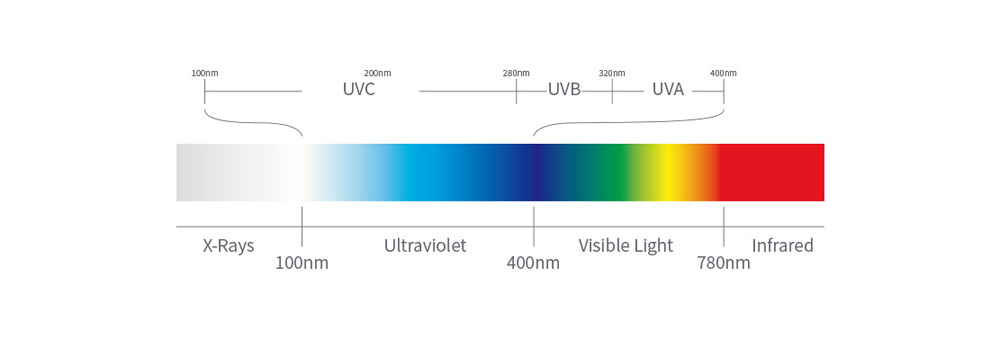

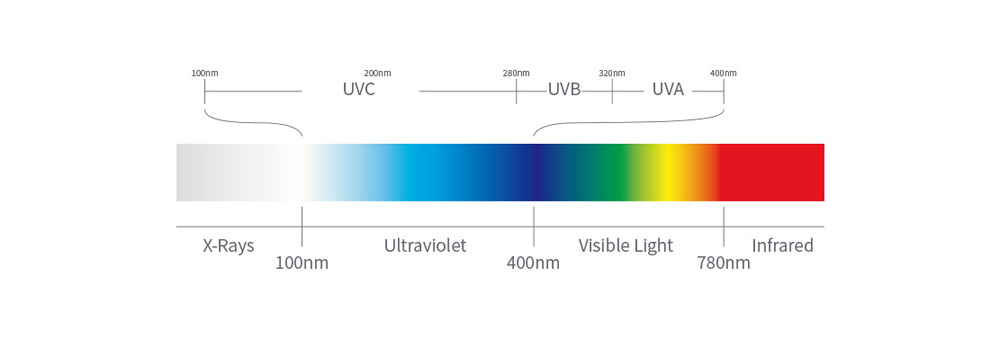

Effective wavelength: UV radiation spans wavelengths from 100–400 nm, but germicidal efficacy is primarily associated with shortwave UVC below 280 nm. UV light sources with wavelengths at 222 nm, 254 nm, and 280 nm are the most commonly used for sterilisation now. Some devices may also adopt 185 nm sources, which generate ozone and enable combined UV + ozone disinfection.

Adequate irradiation: UV sterilisation relies on direct exposure to target surfaces. Therefore, sufficient UV doses must be delivered to the treated surface, determined by factors such as light power output and exposure duration. These need to be calculated with precision. In some structural applications (e.g. UV chambers in water purification systems), the impact of the UV light's unique optical behaviour must also be rigorously assessed.

2、Principle of Optical Specificity

UV light exhibits distinct optical characteristics from visible light. If these are neglected during development, minor errors may lead to product failure; conversely, proper consideration can yield exceptional results:

Low diffraction: Due to its short wavelength, UV light has limited diffraction ability. It can barely bend around objects and essentially only act in straight lines. Therefore, when designing devices that disinfect physical objects, it is essential to minimise obstructions between the light source and the target surface.

Low reflectivity: Unlike visible light, most reflective materials have poor UV reflectance, often less than 10%. Only a few materials, such as polished aluminium and PTFE, can effectively reflect UV. For example, in sterilisation chambers of UVC air germicidal purifiers, using PTFE rather than silver coatings or standard mirrors can significantly improve disinfection efficacy via reflection.

Low penetration: UV is easily absorbed by many substances, including water vapour, dust, and oxygen in the air. Even common transparent materials like standard glass allow little to no transmission of UVC. Only specialised materials such as high-purity quartz or magnesium fluoride crystals offer better UV transmission. This is crucial when designing protective covers for UV light sources.

3、Principle of Safe Usage

Since UV light inactivates microorganisms by affecting proteins and nucleic acids, it can also harm human tissue. Ensuring user safety is a fundamental design obligation:

Human exposure prevention: UV exposure can hurt skin and eyes. Designers must consider user scenarios, operating methods, and functional safeguards to avoid direct exposure. This may be with sensor-based control, delayed activation, physical shielding, or other engineering solutions.

Ozone control: UV at 185 nm can trigger a photochemical reaction with oxygen, producing ozone. Excess ozone is harmful to humans. If 185 nm sources are used, ozone management must be considered, such as through ventilation design or accelerated decomposition design.

4、Principle of Material Suitability

UV photons carry high energy and can trigger strong photochemical reactions, degrading many organic materials. Long-term UV exposure may cause yellowing, embrittlement, cracking, or chalking in plastics, rubbers, coatings, adhesives, and even some fabrics. This impacts both product longevity and safety. Therefore, material compatibility with UV is a key design consideration:

UV-resistant materials: Critical structural parts of UV devices should be made from highly UV-resistant materials, such as stainless steel, anodised aluminium, or PTFE. This helps mitigate the risks of shortened lifespan or reduced efficacy due to material degradation.

UV-resistant treatments: For cost or aesthetic reasons, conventional plastics may be necessary in some areas. In such cases, applying anti-UV coatings or incorporating UV absorbers or stabilisers into materials can improve their resistance to UV exposure.

UV sterilisation has enormous potential, but transforming it into a safe, efficient, and commercially viable product requires deep technical understanding and strict adherence to sound design principles. From precise wavelength and dosage calculations to clever application of optical traits, robust safety measures, and meticulous material selection, every aspect is critical. Whether you are planning a new product or sourcing a bespoke OEM/ODM UV steriliser, we hope this article provides valuable insights.

As a long-standing partner in the field of sterilisation and disinfection equipment ODM/OEM manufacturing, ATYOU Health Tech offers not only end-to-end professional manufacturing services but also shares practical experience and technical insights. If you are looking for a comprehensive disinfection solution, please feel free to contact us at any time. We are here to help you turn your concept into high-quality mass production faster.